How Can You Build a Culture of GMP Awareness Among Employees?

Good Manufacturing Practice (GMP) isn’t just about having the right equipment or documentation — it’s about creating a workplace culture where every employee understands, values, and practices food safety in their daily tasks.

Here’s how you can successfully build and maintain a culture of GMP awareness among your staff.

🎯 Why GMP Awareness Matters

-

Employees are your first line of defense against food safety issues

-

GMP violations often stem from poor habits or lack of training

-

A strong GMP culture leads to:

-

Fewer non-conformities during audits

-

Better product quality

-

Increased customer and regulatory trust

-

✅ Practical Steps to Build GMP Awareness

🧠 1. Regular & Relevant Training

-

Provide GMP induction training for all new hires

-

Conduct refresher training at least once a year

-

Include role-specific examples (e.g., hygiene, labeling, storage)

-

Use visual aids, short videos, and real-life scenarios

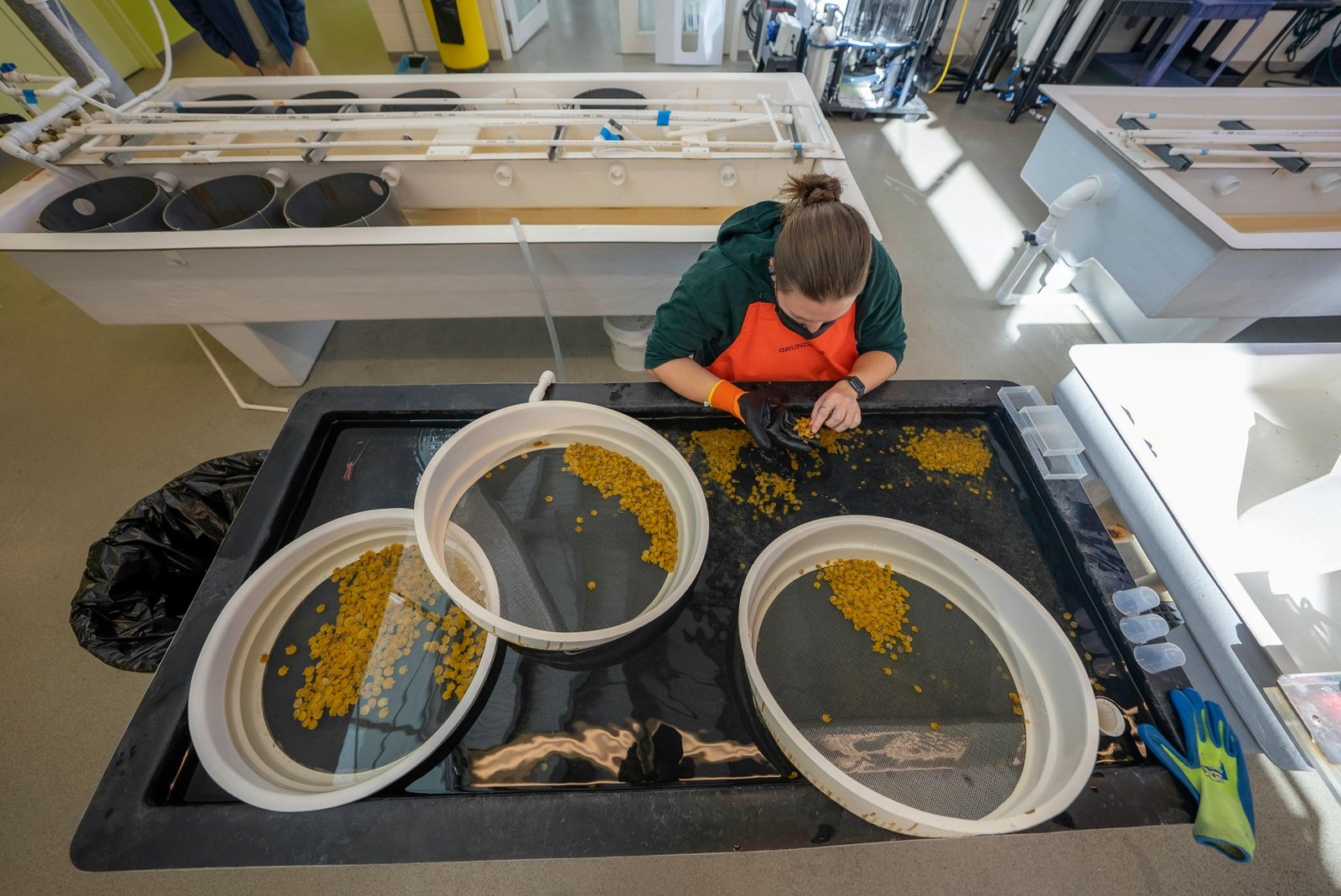

👀 2. Visual Reminders in the Workplace

-

Post GMP posters and checklists in production areas

-

Use color-coded zones for hygiene and material segregation

-

Place signs for:

-

Handwashing stations

-

Allergen controls

-

Personal protective equipment (PPE) rules

-

🧼 3. Lead by Example

-

Supervisors and managers must:

-

Follow GMP rules at all times

-

Correct poor behavior immediately

-

Show commitment during inspections and audits

-

-

Leadership behavior sets the tone for the entire facility

🛠️ 4. Daily GMP Reminders

-

Start shifts with 5-minute GMP talks or toolbox meetings

-

Share quick tips like:

-

“Why clean as you go matters”

-

“How to prevent cross-contamination”

-

“What to do if a foreign object is found”

-

-

Keep messages short, simple, and actionable

📋 5. Empower Employees to Report Issues

-

Set up a clear reporting system (e.g., forms, hotline, suggestion box)

-

Encourage staff to report:

-

Equipment malfunctions

-

Hygiene breaches

-

Packaging or labeling errors

-

-

Reward proactive reporting instead of punishing it

🌟 6. Recognize Good GMP Behavior

-

Implement “GMP Star of the Month” awards

-

Acknowledge teams with zero non-conformities

-

Use noticeboards to share success stories and audit praises

⚠️ Common Challenges in GMP Culture Building

-

Language barriers: Use bilingual training materials

-

Lack of top management support

-

Inconsistent enforcement of rules

-

Outdated training content

-

No follow-up after training sessions

🚀 Quick Wins to Strengthen GMP Culture

-

Involve staff in GMP policy reviews

-

Assign GMP champions in each department

-

Display before-and-after photos for clean-up tasks

-

Conduct mock internal audits with employee participation

-

Rotate staff to different areas for cross-training

🧩 Final Thoughts

Building a culture of GMP awareness takes time, leadership, and consistent action. But when your team takes ownership of food safety, it results in safer products, better audit scores, and a more responsible workforce.

Need help designing a GMP training program or employee awareness campaign?

Talk to CAYS Scientific today — we help food businesses in Malaysia elevate their GMP standards and build strong food safety cultures from the ground up.