Can GMP Help Prevent Cross-Contamination in Multi-Product Facilities?

Can GMP Help Prevent Cross-Contamination in Multi-Product Facilities?

Cross-contamination is one of the biggest risks in multi-product manufacturing, especially in the food, supplements, and pharmaceutical industries. Whether you’re producing allergens, different dosage forms, or high-sensitivity items, Good Manufacturing Practices (GMP) provide the framework to minimize these risks and protect product integrity.

Why Cross-Contamination Is a Serious Concern

-

Can lead to allergic reactions, product recalls, or regulatory penalties

-

Damages consumer trust and brand reputation

-

Affects label claims and product purity

-

Violates GMP and food safety standards like FSSC 22000 and ISO 22000

How GMP Helps Prevent Cross-Contamination

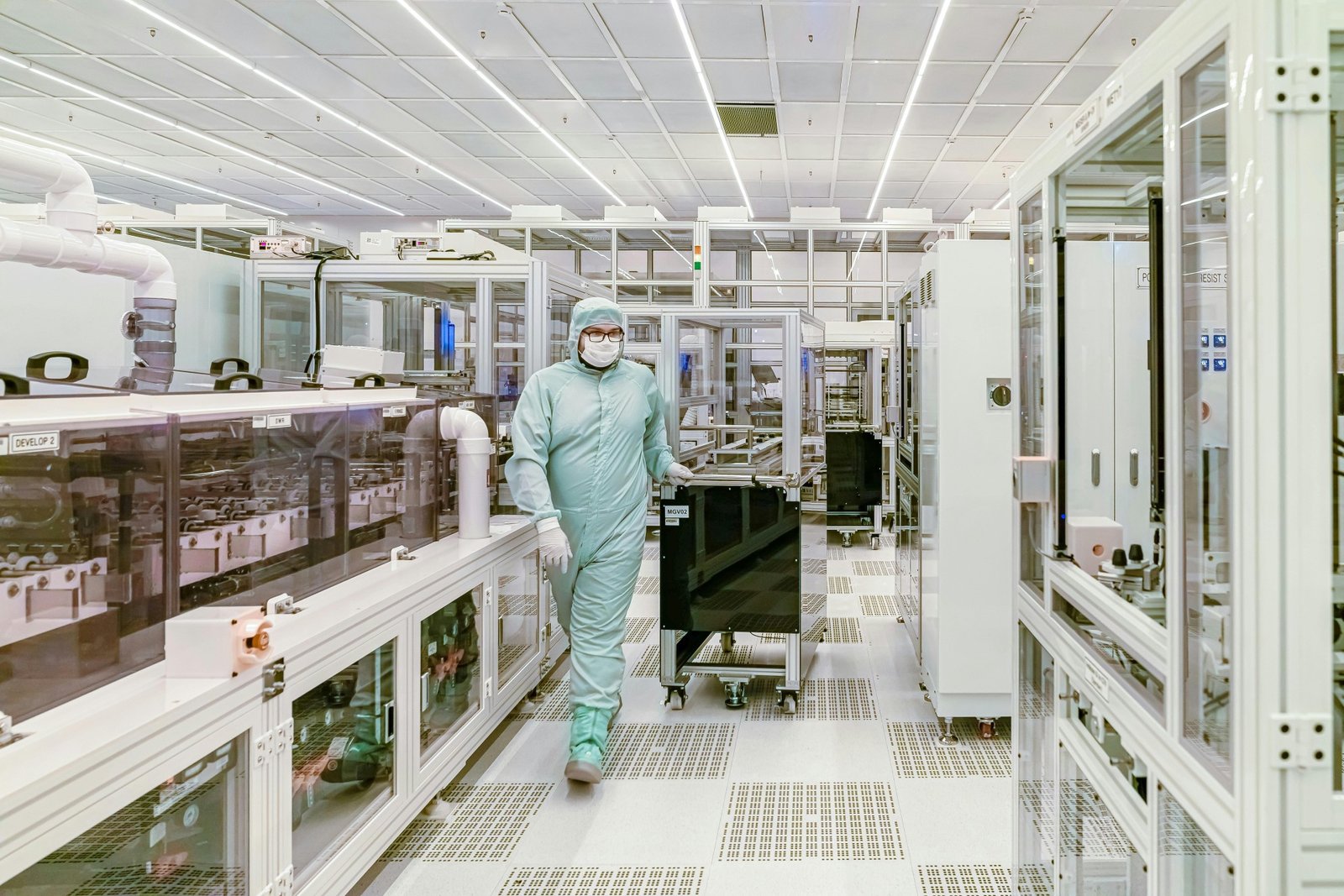

1. Facility Design and Layout

-

Segregated zones for high-risk products

-

Physical barriers between incompatible processes

-

Dedicated air handling systems to prevent airborne contamination

-

Clear material and personnel flow paths to avoid cross-traffic

2. Equipment Control and Cleaning

-

Use of dedicated equipment for specific product lines where necessary

-

Validated cleaning procedures between product changeovers

-

Cleaning logs and verification records maintained consistently

-

Use of color-coded tools and utensils

3. Personnel Hygiene and Behavior

-

Proper gowning procedures for different production zones

-

Handwashing stations at critical control points

-

Staff trained to avoid contamination through improper movement or handling

-

Controlled access to sensitive areas

4. Raw Material and Packaging Segregation

-

Separate storage areas for allergen and non-allergen materials

-

Clear labeling and identification of ingredients

-

FIFO (First-In-First-Out) system to minimize confusion and mix-ups

-

Use of tamper-evident and sealed containers

5. Production and Scheduling Controls

-

Allergen-containing products scheduled at the end of production runs

-

Adequate time and procedures for cleaning between batches

-

Records maintained for product sequencing and changeover verification

-

Risk-based scheduling to reduce cross-contact opportunities

6. Environmental Monitoring and Swabbing

-

Routine swabbing of surfaces and air for allergen or microbial residues

-

Pre-operational inspections to confirm cleanliness

-

Testing of equipment post-cleaning to verify removal of previous product residues

7. Documentation and SOPs

-

Standard Operating Procedures for cleaning, changeovers, and segregation

-

Batch records indicating cleaning status and line clearance

-

Staff trained regularly on updated cross-contamination controls

-

CAPA system in place for any deviations detected

Common Mistakes That Lead to Cross-Contamination

-

Inadequate cleaning between products

-

Reusing utensils or containers without verification

-

Overlapping production lines with shared equipment

-

Poor zoning or unrestricted personnel movement

-

Insufficient allergen control plans

Let CAYS Scientific Help You Strengthen GMP Controls

At CAYS Scientific, we assist multi-product manufacturers to:

✅ Design GMP-compliant facilities and flows

✅ Develop effective cleaning and allergen control programs

✅ Train staff on cross-contamination prevention under GMP

✅ Align your practices with ISO 22000, FSSC 22000, or HACCP

📞 Contact CAYS Scientific today to ensure your facility is safe, clean, and cross-contamination-free.